Product Description

The 8HP series of transmissions is an amazing feat of engineering. The unit is lightweight, strong, and shifts amazing. Like so many other 5th generation transmissions the majority of its internal parts are made of aluminum. While extremely lightweight, aluminum does not have the strength of steel.

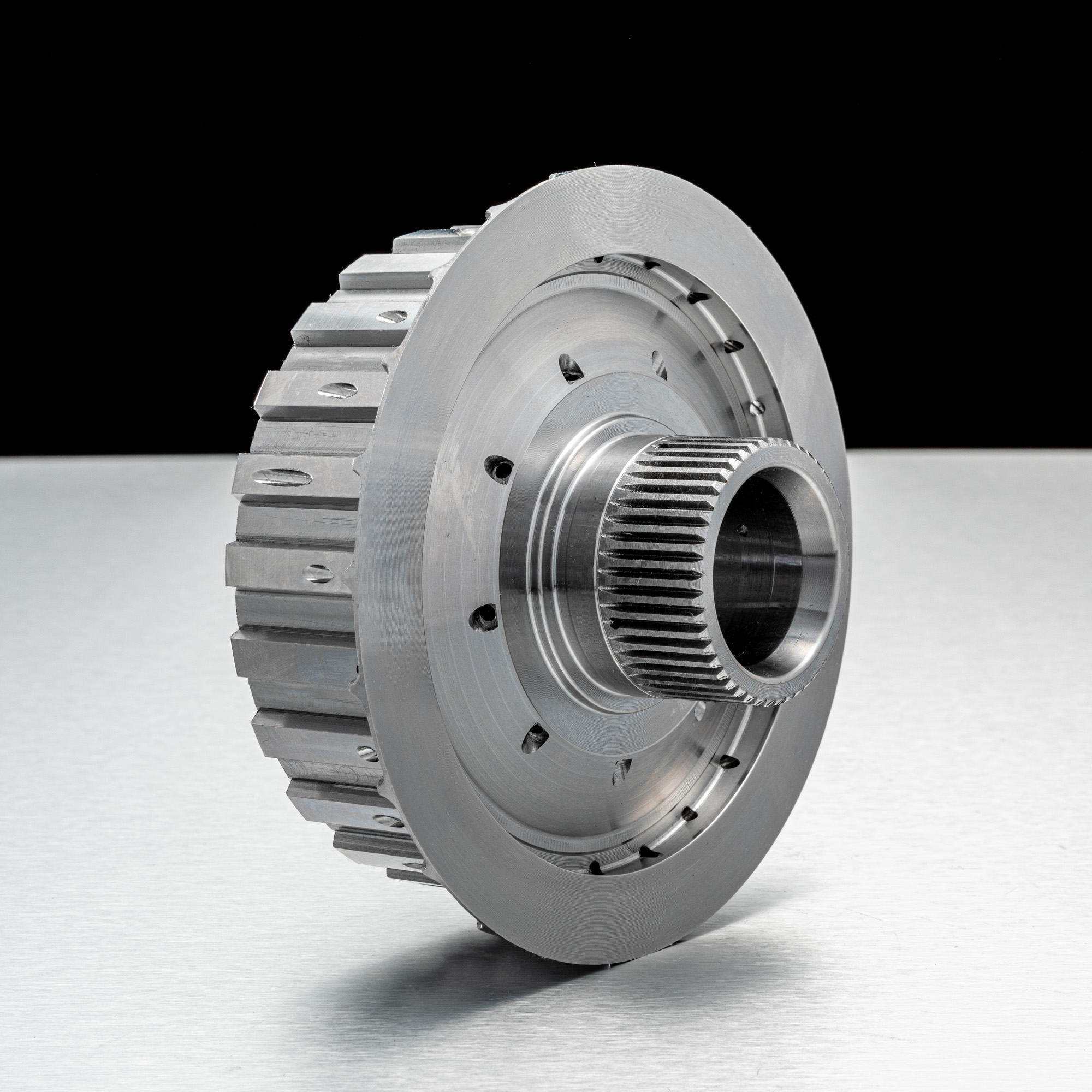

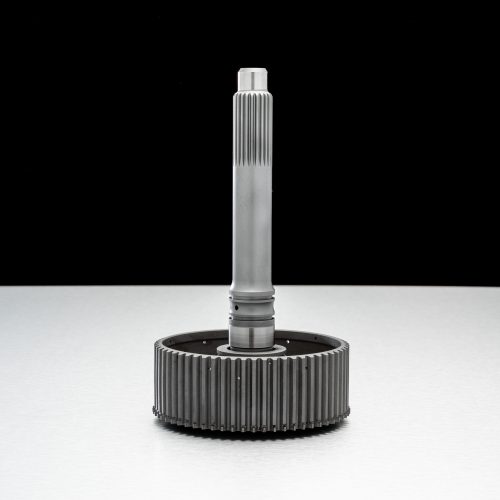

This unit uses aluminum is a very wear prone area. In fact, it’s the first transmission we know of that uses aluminum as a clutch hub. It also uses aluminum as a splined coupling in the E clutch drum. This area is a major concern and it is very common to see either stripped splines, twisted splines or excessively worn clutch hub teeth. These issues are as common on the smaller 8HP45 as they are on the 8HP95.

Our design features a 100% billet steel 4140HTSR clutch hub. This hub will not deform where the steel plates contact it. More importantly, there is no chance of a failure due to the splines stripping or shearing as it does often with the factory aluminum design.

The RevMax Patent Pending E clutch hub assembly fixes all of these issues and also improves rigidity and overall holding capacity. Our design has a shoulder that extends all the way out to the edge of the steel pressure plate to support it. The factory design has tremendous flexing due to the absence of any support area for the pressure plate to rest against. Additionally, we offer billet apply pistons as an upgrade for the 8HP45, 845RE, 870RE, 8HP70, and 8HP75. These pistons feature a full contact area for the apply to contact resulting in cleaner engagement, less deflection, and increased holding capacity. Buy upgrading to the billet piston design allows for the use yet another additional friction and therefore increasing holding capacity even more.

Reviews

There are no reviews yet.